How to Keep and Calibrate Your Industrial Scales Properly

How to Keep and Calibrate Your Industrial Scales Properly

Blog Article

Enhance Your Organization Operations With Reliable Industrial Scales

In today's competitive landscape, the precision of industrial scales plays an essential role in enhancing general organization procedures. Precise considering not only alleviates costly inconsistencies throughout various industries, such as manufacturing and logistics, however likewise makes sure conformity with rigorous market criteria. As businesses look for to enhance performance, understanding the various kinds of scales and their technical innovations comes to be important. The choice process can be complex, and the implications of these options can considerably affect functional success. What factors should be considered to make certain the appropriate tools is picked for your particular needs?

Relevance of Accurate Evaluating

Precise evaluating is crucial in various commercial applications, as also small inconsistencies can bring about considerable operational inefficiencies and financial losses. Industries such as production, logistics, and food processing depend on accurate dimensions to guarantee item quality, governing compliance, and ideal source administration. Unreliable weights can result in overproduction, waste of basic materials, or poor supply, influencing profitability and consumer satisfaction.

Furthermore, accurate evaluating is vital for safety and security and ecological compliance. In the chemical industry, inaccurate measurements can lead to inappropriate combinations, resulting in legal implications or dangerous circumstances. In the food market, specific evaluating is important for adhering to nutritional labeling demands, ensuring that consumers receive exact details relating to the products they buy.

The integration of trusted commercial scales not only improves functional efficiency but additionally sustains data-driven decision-making. Spending in high-grade commercial considering services is critical for organizations aiming to keep an affordable edge in today's dynamic industry.

Kinds Of Industrial Scales

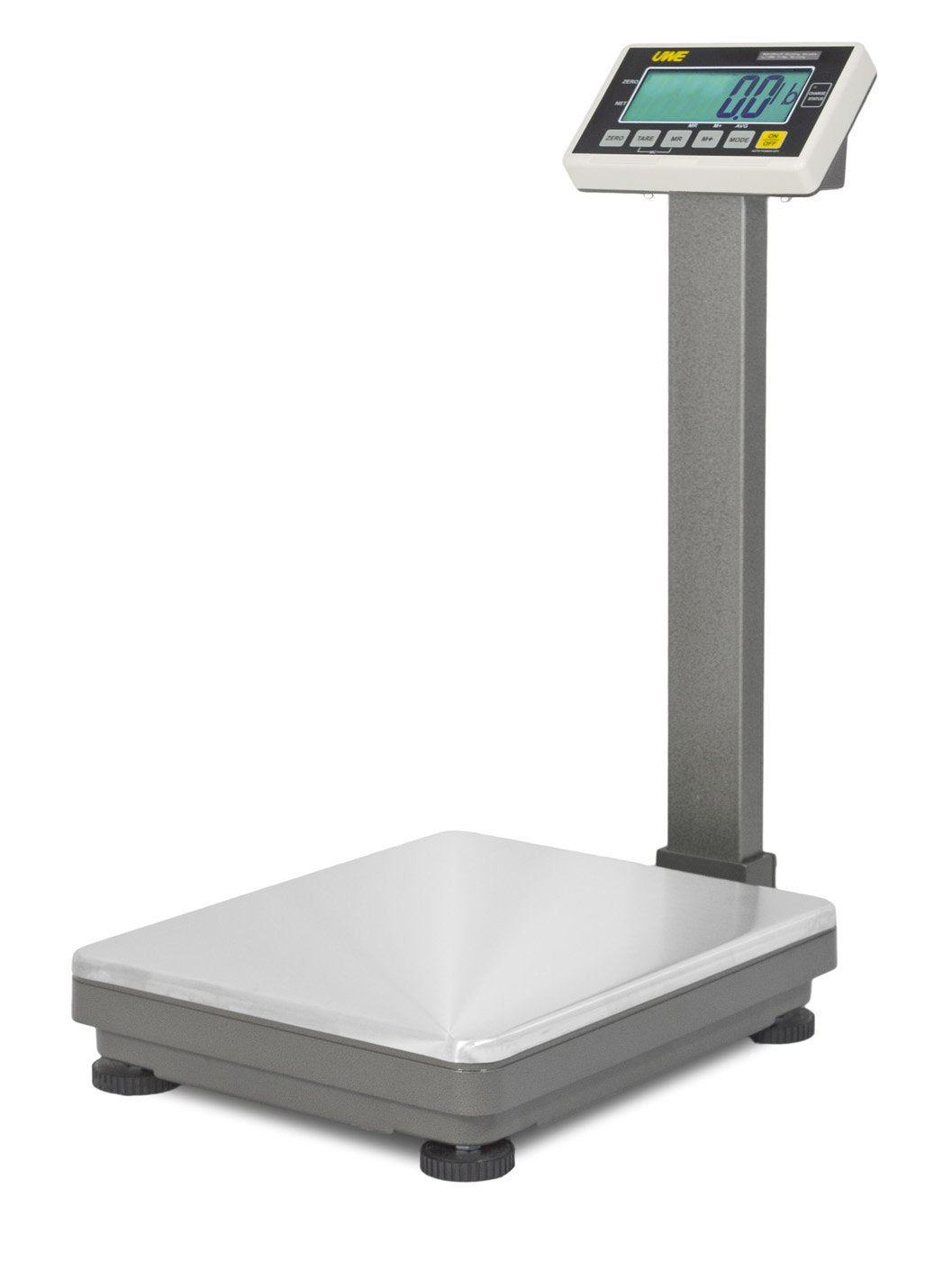

Industrial ranges come in various types, each developed to satisfy details evaluating demands across different industries. Among the most usual kinds are platform scales, which supply a large considering surface suitable for heavy items, making them excellent for stockrooms and manufacturing facilities. These scales usually include electronic displays for very easy analysis.

Another type is bench ranges, which are commonly smaller and portable, perfect for use in laboratories or retail environments. They permit quick dimension of smaller things while keeping precision. For applications calling for the considering of liquids, storage tank ranges are especially designed to gauge the weight of tank, making sure specific stock management.

Crane scales are additionally noteworthy; they are suspended from a framework to evaluate hefty materials in commercial setups. Each kind of industrial range offers an unique function, enhancing functional effectiveness throughout diverse sectors.

Advantages of Modern Technology

In addition, modern-day industrial ranges typically come equipped with connection attributes that enable smooth assimilation with various other systems, such as inventory administration and manufacturing monitoring. This interconnectivity fosters an extra cohesive operations and reduces downtime, as services can keep an eye on performance metrics and make data-driven decisions promptly.

Additionally, many contemporary scales supply user-friendly user interfaces and customizable settings, enabling drivers to adapt their equipment for specific operational requirements. Enhanced durability and durability against extreme ecological conditions even more add to the longevity and integrity browse around these guys of modern scales, guaranteeing they can published here stand up to the rigors of commercial usage.

Picking the Right Equipment

Different markets may call for distinctive kinds of ranges, such as flooring ranges for heavy loads, bench scales for smaller items, or portable scales for flexibility. In addition, taking into consideration the atmosphere in which the scales will be used is crucial. Equipment utilized in harsh environments might need to be resistant and rugged to dirt, wetness, or severe temperature levels.

One more vital element is the modern technology made use of in the scales. Digital ranges typically provide enhanced precision and ease of usage, while analog scales may be adequate for much less requiring applications. It is crucial to assess the scalability of the equipment, guaranteeing that it can suit future development or modifications in manufacturing procedures.

Last but not least, businesses must think about the credibility and dependability of suppliers, as purchasing top quality tools can cause lasting expense financial savings and improved functional efficiency.

Upkeep for Durability

Normal upkeep is crucial for guaranteeing the longevity and ideal performance of commercial ranges. An organized technique to maintenance not just expands the life of the equipment but likewise ensures exact dimensions vital for operational efficiency.

Begin with routine evaluations to determine deterioration, guaranteeing components such as tons cells and display screens work correctly. Calibration checks need to be conducted consistently, ideally after considerable adjustments in ecological problems or complying with heavy use. Precise calibration is essential for compliance with industry requirements and for keeping the integrity of weight dimensions.

Cleansing is an additional essential element of upkeep. Dust, debris, and harsh substances can impair efficiency and bring about errors. Usage proper cleaner and strategies to safeguard delicate parts. Additionally, it is suggested to develop a maintenance routine that tapes each solution go to, calibration, and any repairs performed. This documentation aids in tracking tools efficiency and preparation for future upkeep needs.

Lastly, training staff on appropriate use and treatment techniques will lessen my blog the possibility of driver error, additionally boosting scale integrity. By prioritizing routine maintenance, services can make sure that their commercial scales stay a trustworthy property in their operations.

Verdict

In recap, the combination of reliable industrial scales is essential for improving company operations across numerous fields. Regular upkeep and training additional contribute to the durability and precision of these scales, cultivating data-driven decision-making and inevitably supporting general organization success.

Industrial ranges come in different kinds, each developed to fulfill specific evaluating requirements across various industries. Crane ranges are also noteworthy; they are put on hold from a structure to consider hefty materials in industrial setups.Different sectors may require distinct types of ranges, such as floor scales for heavy lots, bench ranges for smaller products, or portable scales for flexibility - Industrial Scales. Digital scales commonly supply enhanced accuracy and ease of usage, while analog ranges might suffice for less demanding applications.In recap, the integration of reliable commercial ranges is essential for enhancing service operations across various industries

Report this page