Top Benefits of Using an Optical Fibre Diameter Analyser in Optical Fibre Production

Top Benefits of Using an Optical Fibre Diameter Analyser in Optical Fibre Production

Blog Article

Just How an Optical Fibre Diameter Analyser Enhances Quality Assurance in Fibre Production

The assimilation of an Optical Fibre Diameter Analyser into Fibre manufacturing procedures represents a considerable advancement in quality control approaches. By offering real-time, specific measurements of Fibre sizes, this modern technology deals with the vital demand for uniformity in production standards. With its capability to swiftly identify discrepancies and timely rehabilitative measures, the analyser not only enhances product dependability but also adds to overall functional effectiveness. As markets progressively prioritize high quality and compliance, understanding the full impact of such developments comes to be important. What effects could this have for the future of Fibre manufacturing?

Importance of Fibre Diameter Dimension

Accurate measurement of Fibre Diameter is vital in the area of optical Fibre technology, as it straight influences the performance and dependability of Fibre optic systems. The Diameter of an optical Fibre impacts its light-carrying capacity, attenuation, and general transmission performance. Accuracy in measuring Fibre Diameter ensures that the optical residential properties are kept within defined tolerances, which is crucial for optimal signal integrity.

Variations in Fibre Diameter can lead to enhanced losses as a result of scattering and modal dispersion, influencing the high quality of information transmission. In high-speed interaction systems, such discrepancies can cause significant degradation of signal quality, bring about data errors and reduced performance. Consistent Fibre Diameter is vital for compatibility with adapters and splicing technologies, which are essential parts of Fibre optic networks.

Quality control processes in Fibre production greatly depend on accurate Diameter dimensions to make certain conformity with market criteria. By carrying out durable dimension techniques, manufacturers can enhance product dependability, minimize waste, and boost total system efficiency. Therefore, the significance of Fibre Diameter dimension can not be overstated, as it works as a keystone in the advancement of optical Fibre technology and its applications in contemporary communication networks.

How the Analyser Works

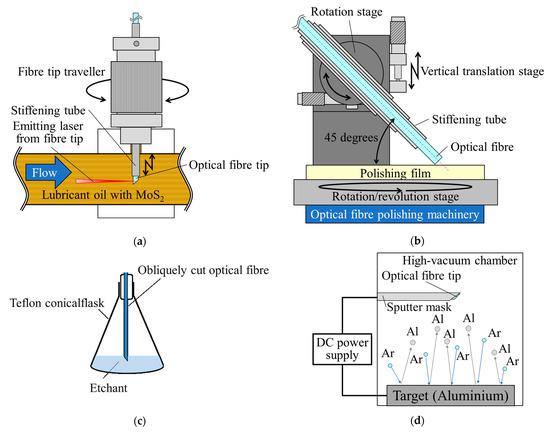

The efficient measurement of Fibre Diameter relies on sophisticated logical techniques that guarantee precision and reliability in optical Fibre production (optical fibre diameter analyser). The Optical Fibre Diameter Analyser employs a combination of laser innovation and progressed image handling formulas to accurately evaluate the Diameter of fibers as they are created

Initially, a laser beam of light is guided at the moving Fibre, developing a cross-sectional shadow. The analyser catches this shadow making use of high-resolution cams placed purposefully along the manufacturing line. The captured photos are then refined in real-time to identify the Fibre's Diameter with outstanding accuracy.

The system utilizes advanced formulas that account for various elements, consisting of variants in light intensity and ecological conditions, to improve dimension reliability. It can spot minute modifications in Diameter, such as fluctuations that may take place throughout the manufacturing process.

Additionally, the analyser is capable of taking care of multiple fibres at the same time, enhancing throughput without endangering accuracy. By offering instant feedback on the Diameter, the Optical Fibre Diameter Analyser plays an essential duty in maintaining stringent high quality control standards, making certain that the end product meets industry specs and consumer needs.

Benefits of Real-Time Tracking

While typical methods of keeping an eye on Fibre Diameter usually involve taxing post-production checks, real-time surveillance considerably enhances the performance and high quality of optical Fibre manufacturing. optical fibre diameter analyser. This proactive technique permits suppliers to determine discrepancies in Fibre Diameter as they happen, rather than waiting till manufacturing is complete to examine high quality

By continuously gauging the Diameter during manufacturing, suppliers can make certain that the fibers fulfill strict specs, resulting in minimized irregularity and enhanced uniformity. Real-time monitoring additionally enables immediate rehabilitative actions to be taken, decreasing waste and avoiding defective fibres from entering the supply chain.

Additionally, this technology helps with improved data collection and analysis, providing understandings into production trends and prospective locations for renovation. Such data-driven decision-making encourages suppliers to enhance procedures and maintain high criteria of high quality control.

On top of that, real-time tracking cultivates a society of constant enhancement within the production setting. Staff members are extra involved when they can see the impact of their operate in real-time, causing heightened accountability and a commitment to excellence. On the whole, the execution of real-time tracking systems in from this source optical Fibre manufacturing equates to remarkable item high quality and raised client satisfaction.

Effect On Manufacturing Efficiency

Executing optical Fibre Diameter analysers considerably boosts manufacturing efficiency by simplifying the production procedure. These devices facilitate continual tracking of Fibre Diameter, allowing suppliers to spot inconsistencies in real-time. By identifying inconsistencies promptly, production lines can be readjusted quickly, decreasing downtime and reducing the chance of generating malfunctioning items.

Furthermore, the combination of these analysers into the production operations makes it possible for better resource allowance. With exact Diameter measurements, operators can enhance material use, making sure that sources are not wasted on flawed fibers. This precision also adds to less junk and rework, ultimately lowering manufacturing prices.

The automation provided by optical Fibre Diameter analysers decreases reliance on manual assessments, which are susceptible and frequently time-consuming to human error. Because of this, workers can concentrate on even more calculated jobs, improving total productivity.

Furthermore, the data created from these analysers can educate process enhancements and promote much better decision-making. By analyzing trends in Fibre Diameter variations, makers can carry out aggressive procedures to improve production techniques and maintain regular high quality. In recap, optical Fibre Diameter analysers play a crucial duty in improving production performance, causing greater quality result and increased productivity.

Study and Success Stories

Across various industries, study highlight the transformative influence of optical Fibre Diameter analysers on production procedures. One popular instance is a leading telecoms company that faced view publisher site obstacles with inconsistent Fibre sizes, bring about raised rejection prices. By incorporating an optical Fibre Diameter analyser, the firm achieved real-time surveillance of Fibre measurements, causing a 30% decrease in flaws and significant expense financial savings.

In addition, a study institution focusing on advanced materials used optical Fibre Diameter analysers to improve their speculative processes. The analyser's capability to provide in-depth understandings into Fibre uniformity enabled the advancement of ingenious materials with improved efficiency attributes.

These success stories highlight the essential duty of optical Fibre Diameter analysers in improving top quality control, improving production effectiveness, and driving technology across varied industries.

Final Thought

In verdict, the Optical Fibre Diameter Analyser plays a critical function in enhancing quality control within Fibre production. As demonstrated with numerous case studies, the analyser confirms vital for accomplishing premium product high quality in Fibre production.

The implementation of optical Fibre Diameter analysers permitted for rigid quality control, guaranteeing that the generated fibres fulfilled exacting industry requirements.In verdict, the Optical Fibre Diameter Analyser plays a crucial function in enhancing top quality control within Fibre production.

Report this page